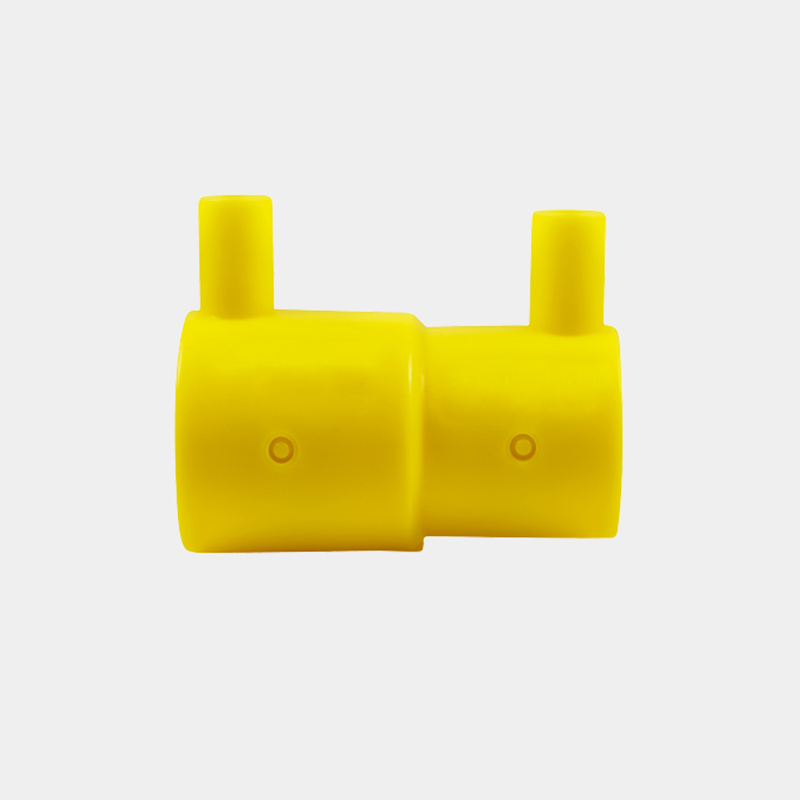

Electrofusion Fittings

These fittings are specifically designed for connecting polyethylene (PE) pipes using an electrofusion process, where an electrical energy is used to heat the fitting and the pipe's surface, fusing them together & making a homogenous joint.